You cannot serve a quality draft beer unless you are using the proper gas system.

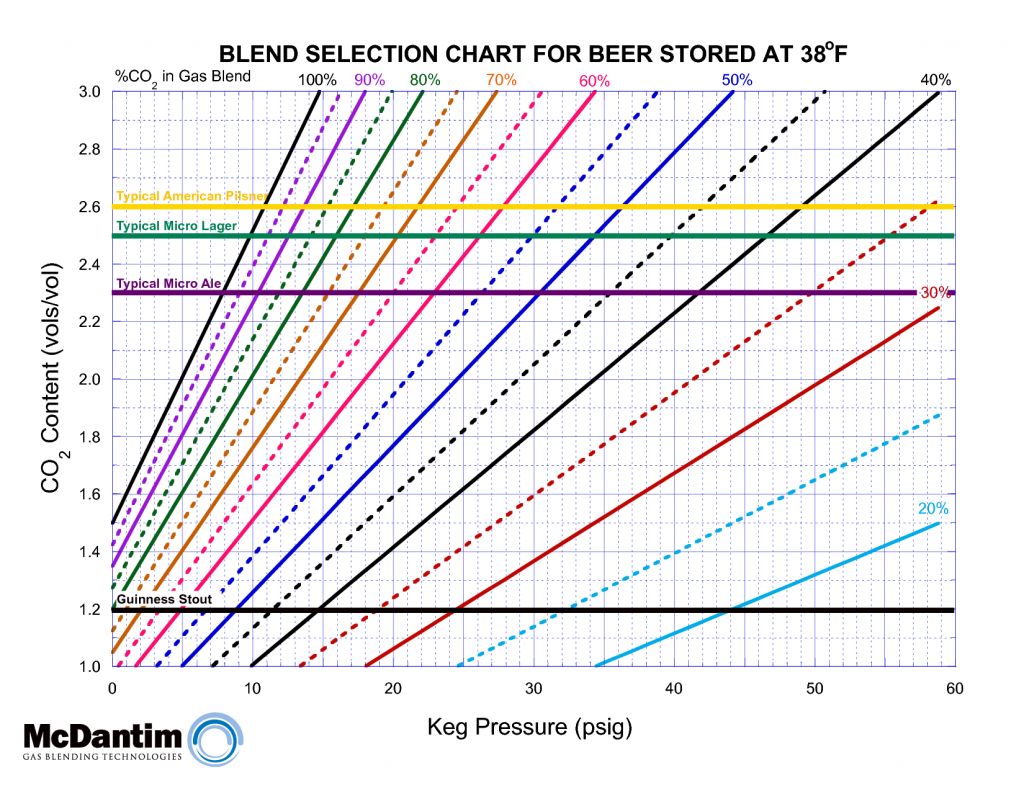

Gas is used to propel the product from the barrel to the point of dispense. The pour pressure is used to set the pour speed (2oz. per second). The gas is also used to maintain the carbonation level in the product to the specifications the brewer intended. All beer systems have a set of parameters that will dictate which type of gas system can be used. All carbonated fluids use a combination of temperature and pressure to keep the gas in solution (bubble in the fluid).

If you are using a pre-mixed 75/25 N2/CO₂ gas (better known as Beer Gas) to push and maintain your entire beer system, your beer sucks. A high Nitrogen content on a carbonated beer will cause the beer to be flat, create waste & lost revenue.

If you are using 100% CO₂ to push your beer, you cannot exceed 14psi keg pressure or you will over-carbonate the beer. This will cause excessive foaming (waste) especially towards the bottom of the barrel, making you change the barrel prematurely and losing revenue. Over-carbonated beer will also not maintain the “as brewer intended” standard causing the product to taste different than intended. It can also lead to the customer getting bloated due to the high rate of release of CO₂ in the stomach.

Using the correct gas is critical to not only the quality of the product but it will also reduce the operating cost of the beer system.